Bioenergy with carbon capture and storage (BECCS) is an engineered CDR technique that involves capturing and permanently storing CO2 from processes where biomass is converted into fuels or directly burned to generate energy.

BECCS follows a closed-system pathway, meaning it involves a high degree of human control and the sequestration of a known quantity of carbon in a controlled environment.

Open-system pathways are currently less favoured than closed-system pathways because they take longer to meet the standards of ecosystem safety, pricing, and quantification measurement required for effective and long-lasting CDR. In simple terms, BECCS is less risky compared to enhanced rock weathering, Ocean alkalinity enhancement, and ocean biomass sinking.

BECCS has a global removal potential of approximately 1–5 Gt CO2 annually at scale.

What makes BECCS the leading credit by volume in the CDR market?

BECCS has been gaining attention due to its ability to geologically store CO2 while producing energy. This creates multiple revenue streams, leading more power plants to consider incorporating BECCS into their supply chains.

The benefits of decarbonizing the energy sector and removing CO2 have given BECCS a central position in nationally determined contributions. Thanks to proven technologies, it is easier to deploy compared to other engineered CDR solutions. Operational bioenergy plants can be retrofitted with CCS technology rather than starting from scratch.

BECCS delivers a triple benefit:

- Negative emissions essential for fighting the climate crisis

- Clean economic growth - preserving and creating jobs

- Reliable renewable electricity to support the grid as more wind and solar are connected

How does BECCS actually work?

This process can be broken down into five key steps:

1. Sustainable Biomass SourcingBiomass feedstocks can include oil, sugar, and starch crops, manure, municipal solid waste (MSW), and wood.

It is crucial to ensure that the biomass is sustainably sourced and, if possible, certified by recognised standards. For example, when sourcing wood, certifications such as the Sustainable Forest Initiative (SFI), the Forest Stewardship Council (FSC), or the Programme for the Endorsement of Forest Certification (PEFC) can be used to verify sustainability.

2. Biomass Processing and TransportThe biomass must be processed (cut, mixed, grinded, dried) and pelletised to achieve optimal biomass conversion rates. Once processed, it is transported to the plant for energy generation and CO2 capture.

3. Biomass ConversionThere are two main types of biomass conversion used in BECCS:

- Biochemical Conversion

- Anaerobic digestion

- Thermochemical Conversion

- Gasification

- Pyrolysis

- Torrefaction

4. Energy Generation

During the biomass conversion process, energy is generated in the form of electricity and heat. This energy is renewable and can be used to supply power to the grid or for industrial purposes.

5. CO2 Capture, Transport, and UtilisationCaptured CO2 is transported to onshore or offshore storage facilities for geological sequestration. In some cases, the CO2 is utilised in the production of other products, such as: dry ice, paper, carbonated beverages, aviation fuel, polymers, etc.

At the end of the process, the amount of CO2 geologically captured must exceed the total CO2 emissions generated throughout the entire supply chain to ensure a net-negative impact on the atmosphere.

Current state of BECCS in the CDR market

The BECCS sector is experiencing rapid growth within the carbon dioxide removal (CDR) market, with approximately 40 projects globally in our database. Only 10 of these projects are currently selling carbon removal credits, while the rest are in various stages of development. Some of the hurdles these projects face include:

- Obtaining legal contracts for CO2 storage and transport

- Awaiting methodology verification

- Securing pipeline permissions,safety licences,Environmental certifications.

The majority of BECCS projects are retrofits to existing CHP, power, biogas, and ethanol production plants. While this approach significantly reduces capital expenditure (CAPEX) compared to building new plants, it often results in higher operating expenses (OPEX)

Current landscape of the BECCS market

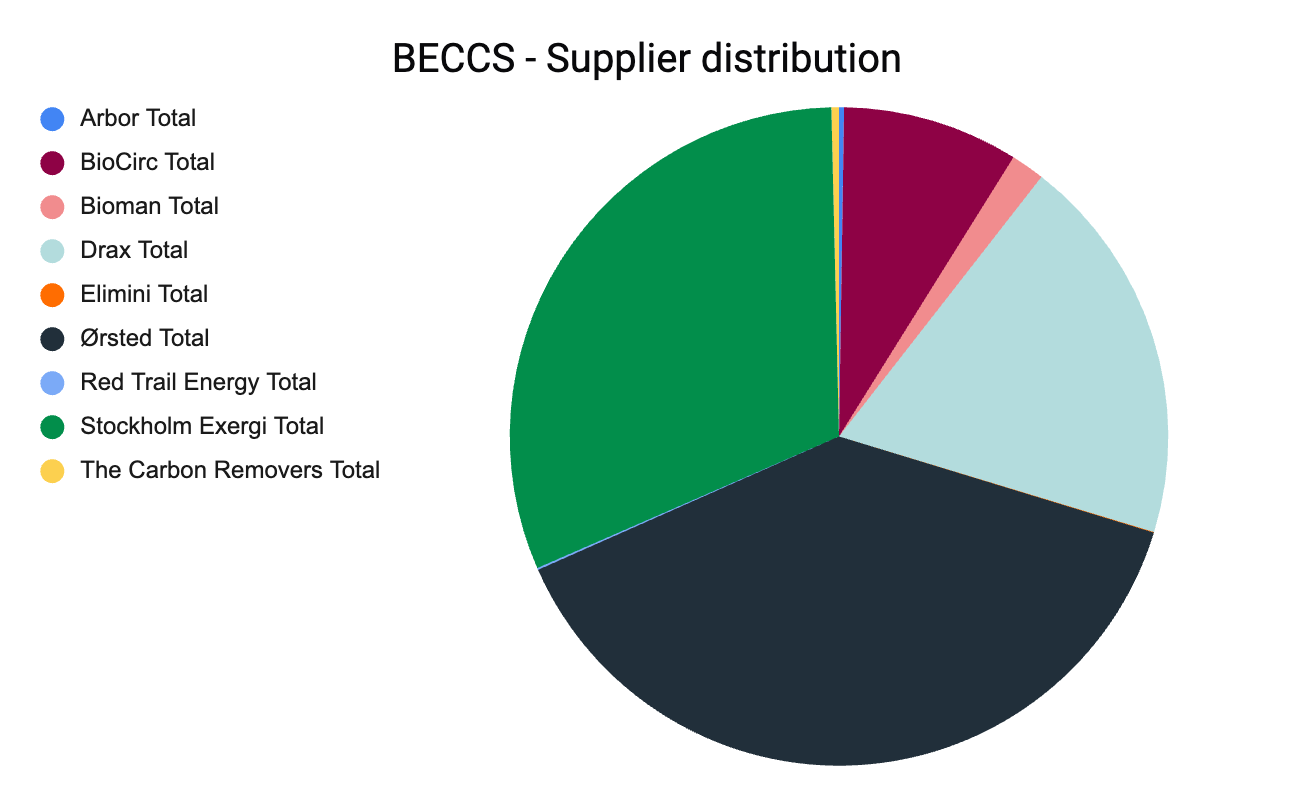

- 10 suppliers have sold approximately 11 million tonnes of carbon removal credits, including both direct purchases and memorandums of understanding (MOUs).

- Stockholm Exergi, Ørsted, and Drax collectively accounted for 89% of all the BECCS credits sold to date.

- The average price of a BECCS credit is $389.

- Microsoft has contributed to 67% of the total BECCS credits sold to date, making it the largest buyer in the market.

- Denmark (NECCS fund) accounted for 11% of the total credits subsidized, supporting Bioman, BioCirc, and The Carbon Removers through a subsidy program aimed at meeting its Nationally Determined Contributions (NDCs).

- Respira International has secured 19% of the total credits sold through a MOU with Drax.

- Northern Lights, Vikingccs, Greenport Scandinavia, and Gas Storage Denmark are the most common geological storage partners.

The BECCS market is currently dominated by projects in European countries. This trend is likely driven by supportive government policies and the region's focus on achieving net-zero emissions.

Challenges faced by BECCS

Despite the technology’s potential, BECCS developers are also facing some headwinds. These include:

- Incomplete carbon accounting: BECCS developers often rely on limited Life Cycle Assessments (LCAs) that fail to account for significant emissions sources, such as land-use change, CO2 leakage during underground injection, and potential re-release of captured carbon if used for other purposes.

- Biomass availability and sustainability: The demand for biomass for BECCS competes with its use in food, feed, construction, and other industries. As demand continues to rise for biomass, its price will also increase, leading to higher input costs for BECCS developers.

- High costs: Implementing new BECCS projects is expensive, requiring significant capital expenditure for technology and infrastructure.

- Public opposition to CO2 pipelines: Large-scale BECCS projects in the US often involve extensive pipeline networks, facing opposition from communities concerned about safety, environmental impacts, and property rights.

Conclusion

The actual CO2 removed from the atmosphere via BECCS depends on many factors including the nature of the biomass, its cultivation, densification and transport, and the end use and CO2 capture efficiencies.

BECCS is a promising CDR technology offering negative emissions, renewable energy, and economic growth. While it faces challenges like high costs, sustainability concerns, and regulatory hurdles, its proven scalability and growing market presence make it a key player in achieving global net-zero targets.