Capturing carbon dioxide from the air at a low cost can be done by plants, trees, and any other biomass. However, forests and other biomass sources eventually reach a storage capacity limit¹, and most of the carbon stored in plants is released back into the atmosphere when they die². To overcome this issue, Bioenergy with Carbon Capture and Storage (BECCS) is a potential solution.

BECCS is a carbon dioxide removal (CDR) technology that involves generating energy from biomass (such as plants or agricultural waste), capturing the carbon dioxide that is released during the process, and storing it underground instead of releasing it into the atmosphere. The goal of BECCS is to produce energy while reducing and removing greenhouse gas emissions, making it a potential tool for mitigating climate change.

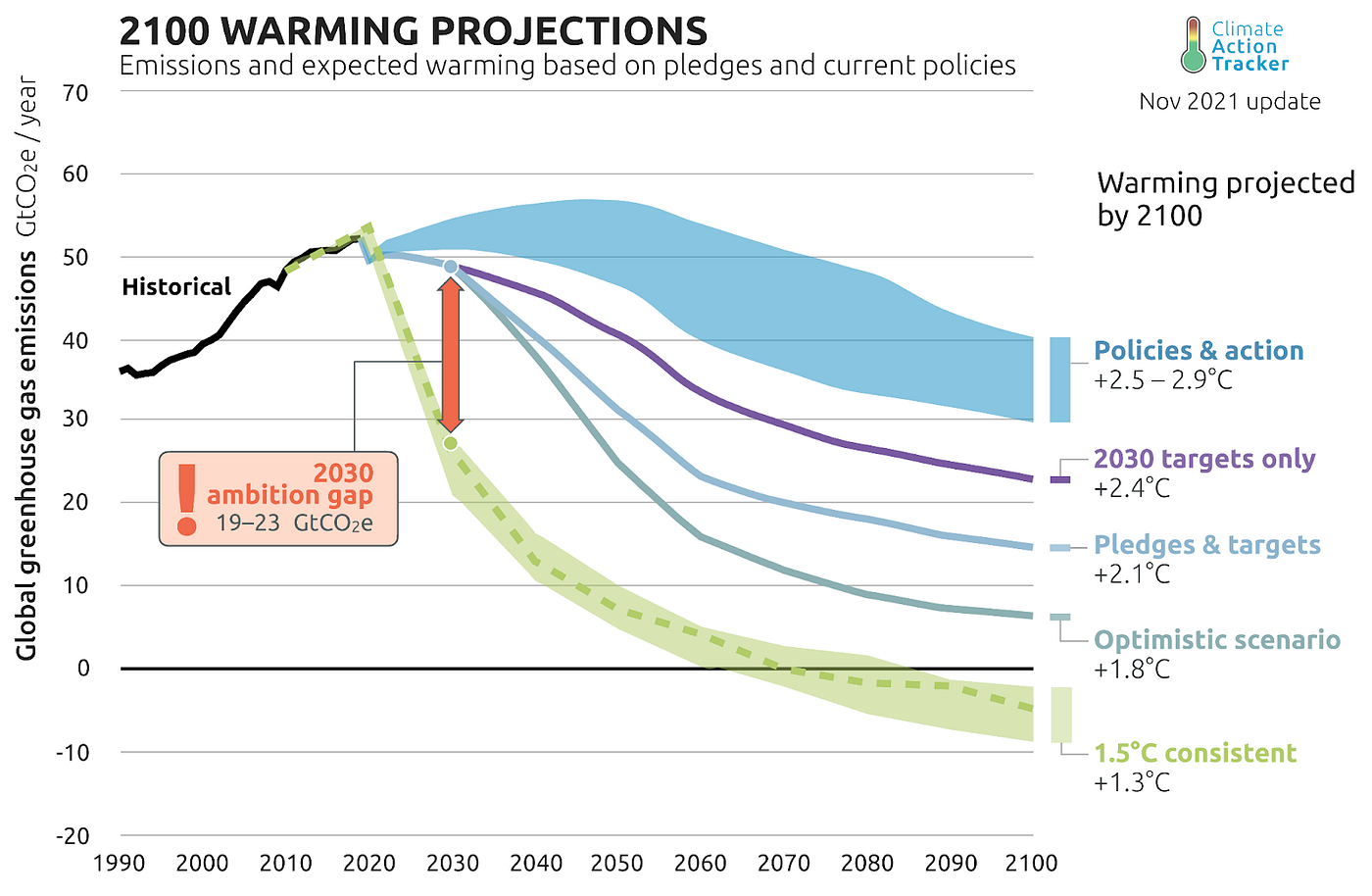

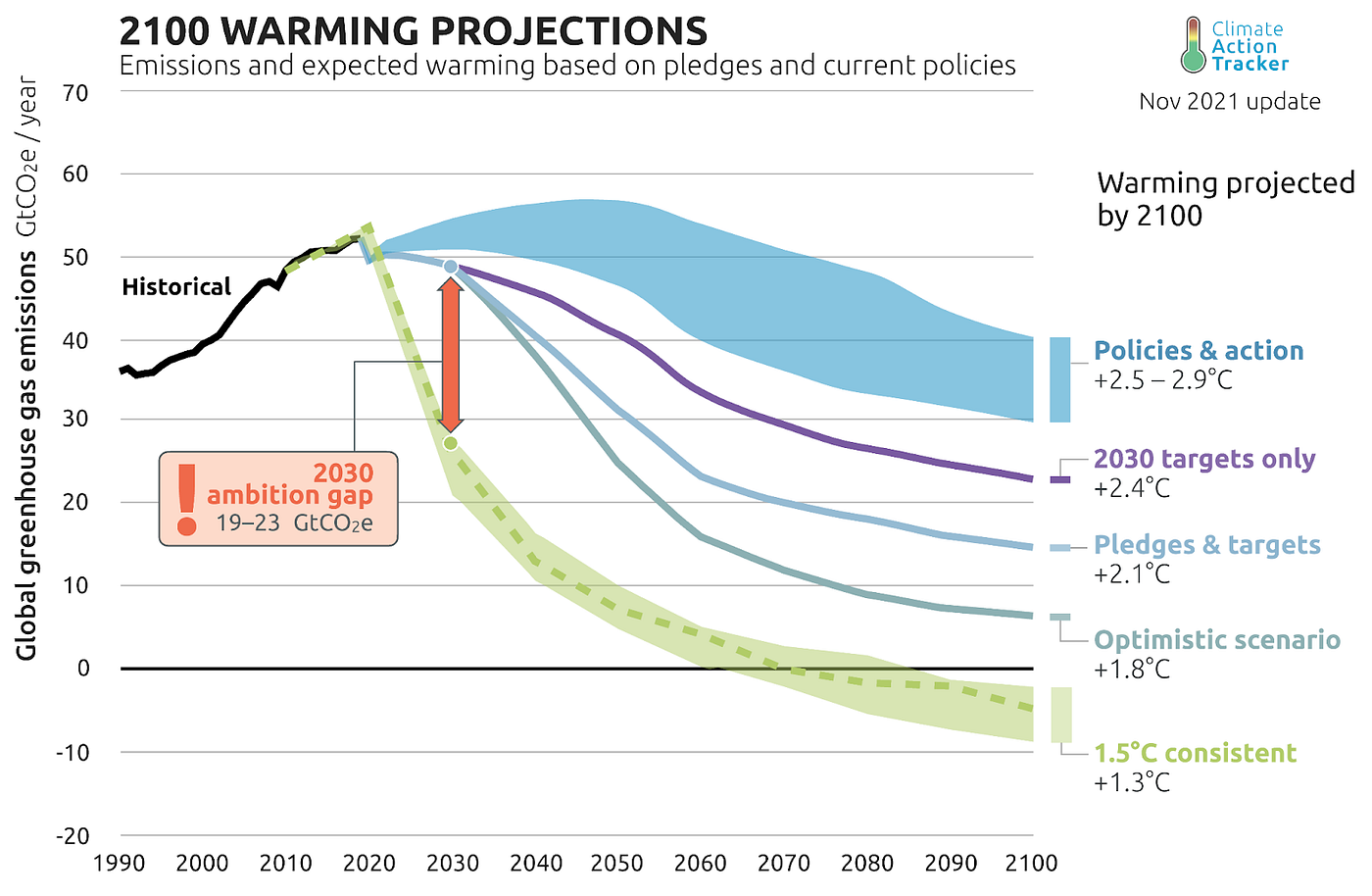

The importance of scaling CDR technologies is paramount. The latest IPCC report states that to reach 1.5 degrees by 2050, we cannot just use avoidance and reduction carbon methods alone, but also need to supplement them with CDR technologies. Figure 1 by Climate Action Tracker, using IPCC projections, illustrates the emission gap we need CDR technologies to remove; we need to reach approximately 19–23 GtCO2/year by 2030 to reach the 1.5 degree target by 2050. This is a monumental task and it requires a global effort to realise it.

BECCS is one of the most advanced and economic CDR technologies available currently and is part of a suite of CDR technologies that are being quickly developed and scaled to realize this goal.

BECCS currently removes 2m tCO2/year with approximately 15 pilot and demonstration plants, and one large operational plant in Illinois in the USA³. This plant has been capturing 1m tCO2 per year for permanent storage in a deep geological formation since 2018. There are five other key development plants in Norway, UK, Japan, and the Netherlands. BECCS is expected to sustainably sequester 2–4 GtCO2/year using 25% of global managed forest resources, 130Mha of woody energy crops and 10Mha of conventional bioenergy crops for biomass input by 2050.⁴

The questions are: will BECCS be able to scale to this level in the future, and how are we expecting it to affect the voluntary carbon market VCM?

This blog is going to focus on how the BECCS technology works, and answer this key question.

Understanding BECCS

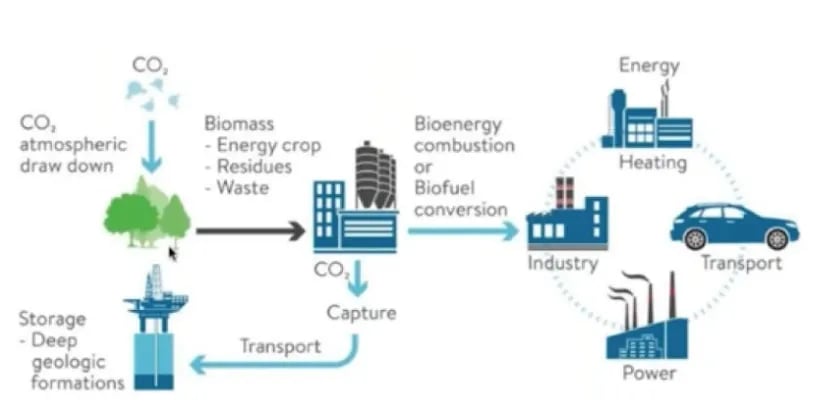

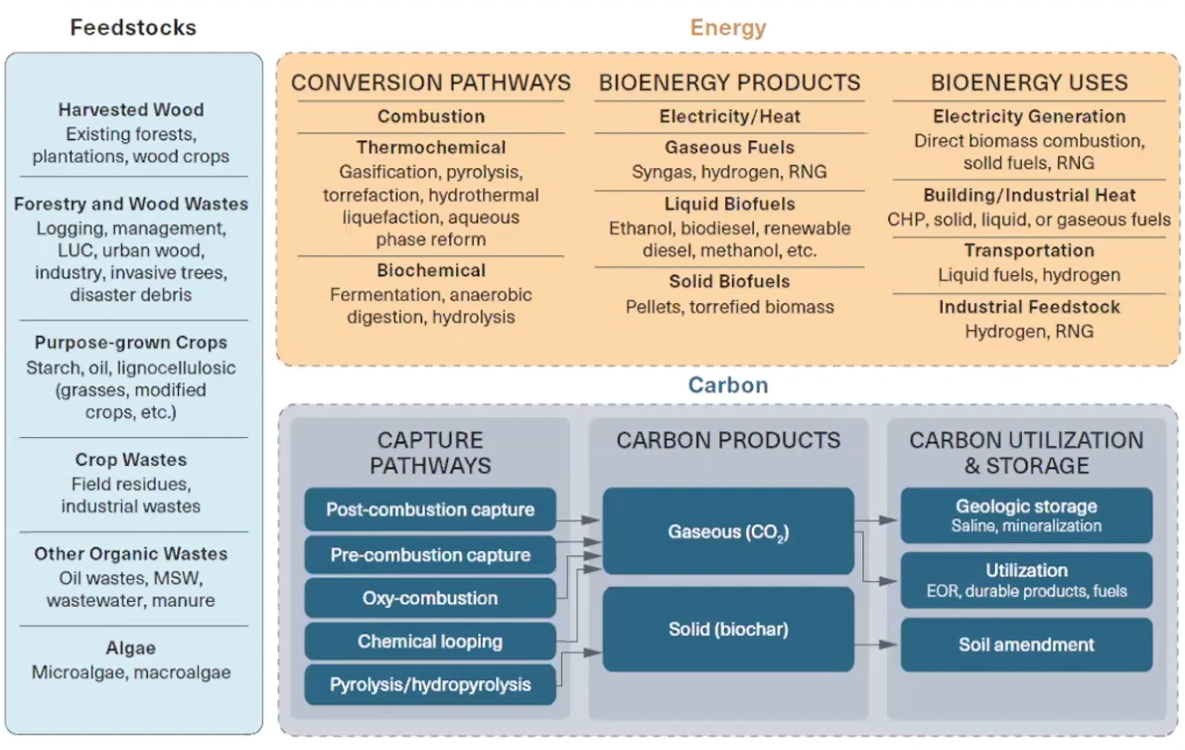

BECCS is one of the many proposed CDR technologies, visualised in Figure 2 by the American University. It is a unique technology relative to others because it is both a biological and engineered method of CDR.

BECCS uses biomass and biological inputs such as plants to capture CO2 from the short term terrestrial carbon cycle and either:

1. Stores it in the long term carbon cycle in deep geological reservoirs.

2. Uses engineered methods to process the biomass and create carbon negative materials and products or substitute fuel and energy sources for traditional hydrocarbons, which are part of the long term geological carbon cycle. Because BECCS uses biomass sources that contain CO2 from the short term terrestrial carbon cycle, fuels generated by it therefore reduce the total volume of CO2 that is entering the atmospheric system overall by reducing the amount of hydrocarbons used.

A diagram of the BECCS system of these two outputs can be visualised in Figure 3 from the Global Carbon institute.

As a summary, BECCS works in this linear process:

BECCS involves the conversion of biomass into usable energy. This process typically involves the following steps:

- Feedstock production: Biomass is grown and harvested from sources such as agricultural crops, forestry residues, or dedicated energy crops.

- Conversion: The biomass is converted into energy through various processes, such as combustion, gasification, or anaerobic digestion. This produces heat, electricity, or fuels such as bioethanol or biodiesel.

- Carbon capture: During the conversion process, carbon dioxide (CO2) would typically be released into the atmosphere. In BECCS, this CO2 is captured using carbon capture technologies, such as post-combustion capture, pre-combustion capture, or oxyfuel combustion.

- Transport: The captured CO2 is transported to a storage site, typically via pipelines or tanker trucks.

- Storage: The captured CO2 is stored underground in geologic formations such as depleted oil and gas reservoirs, saline aquifers, or coal seams.

By capturing and storing the CO2 emitted during the bioenergy process, BECCS can reduce net greenhouse gas emissions and help mitigate climate change. Additionally, the use of biomass as a feedstock for energy production can be a sustainable alternative to fossil fuels, as long as the biomass is produced and harvested in an environmentally responsible manner.

The importance of CCS in BECCS and its constituents

Carbon capture and storage plays a critical role in BECCS by capturing the CO2 that is released during the bioenergy process and storing it underground instead of releasing it into the atmosphere. Without CCS, the emissions from bioenergy would still contribute to climate change, as the CO2 would be released into the atmosphere like any other combustion process.

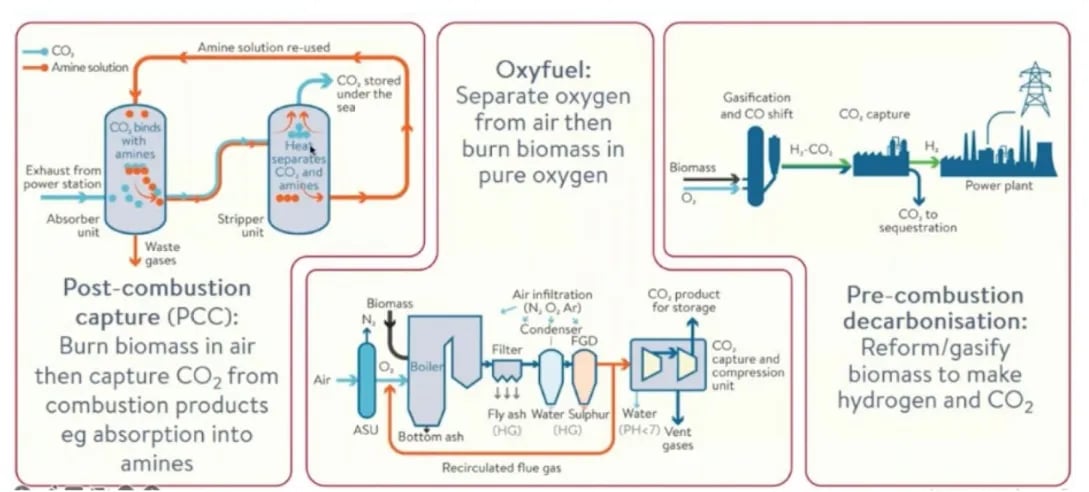

In BECCS, the CCS process involves capturing the CO2 from the bioenergy facility using technologies such as post-combustion capture, pre-combustion capture⁵, or oxyfuel combustion.

These are outlined in Figure 4:

1. Post-combustion capture is a process in BECCS which captures CO2 from biomass combustion products. The flue gases containing CO2 are absorbed into amines, a type of chemical solvent, which then undergoes a process called stripping. Stripping releases the captured CO2 from the amine solution, which can then be stored or utilized. The stripping process is energy-intensive, requiring heat to release the captured CO2, which can impact the efficiency of the BECCS system. However, research and technological advancements aim to minimize the energy required for stripping, making it a promising solution for mitigating climate change.

Stripping is also a mechanism that is used in liquid direct air capture (DAC) and one of the largest energy costs, another motivation for greater research into the technology. DAC units can be used in synergy with BECCS in this process. See our blog here to read about the mechanisms of DAC.

2. Oxyfuel combustion is a process that involves burning biomass in a mixture of oxygen and recycled flue gases, instead of air. The flue gases containing carbon dioxide (CO2) are separated from nitrogen using a filter and then condensed, resulting in a concentrated stream of CO2 that can be stored. The remaining flue gases can be recycled back into the

system to reduce energy consumption. Overall, the oxyfuel combustion technology in BECCS enables the production of negative emissions, helping to mitigate climate change.

3. Pre-combustion decarbonization is a specific type of BECCS that involves capturing and removing the carbon dioxide before the bioenergy is burned.

In the pre-combustion process, the biomass is first converted into a gas (called syngas) through a process called gasification. During this process, the syngas is passed through a filter or solvent that captures the carbon dioxide, separating it from the other gases in the syngas. The carbon dioxide is then compressed and stored in underground geological formations, while the remaining gases are burned to produce electricity or heat.

The advantage of pre-combustion decarbonisation is that it can capture a higher percentage of the carbon dioxide emissions produced by the bioenergy process than post-combustion decarbonisation, where carbon capture happens after combustion has already occurred. This can make the process more efficient and effective at reducing greenhouse gas emissions. However, pre-combustion decarbonisation requires additional equipment and infrastructure, which can increase the cost and complexity of the BECCS process.

The captured CO2 from any of these separation processes is then compressed and transported to a storage site, where it is injected deep underground into geologic formations such as depleted oil and gas reservoirs, saline aquifers, or coal seams. The stored CO2 is then monitored to ensure it remains securely stored and does not leak back into the atmosphere.

By capturing and storing CO2 emissions, BECCS can achieve negative emissions, which means that more CO2 is removed from the atmosphere than is emitted during the bioenergy process. This negative emissions technology is important for meeting climate change mitigation goals, as it can help offset emissions from sectors that are difficult to decarbonize, such as aviation or heavy industry. Additionally, the use of CCS in BECCS can also reduce the cost of carbon mitigation by allowing existing fossil fuel infrastructure to be used while still reducing emissions.

Current state of BECCS development

According to current early and advanced stage BECCS projects, the removal of carbon is projected to reach approximately 40m tCO2 per year by 2030, which is insufficient compared to the estimated 250m tCO2 per year needed to achieve the Net Zero Emissions by 2050 Scenario. Nevertheless, BECCS has gained significant momentum in recent years, with the announcement of over 50 new facilities involving BECCS, with a total biogenic capture capacity of around 20m tCO2 per year, between January 2021 and June 2022. These facilities cover various BECCS applications and are supported by company and country-level net zero commitments.⁶

BECCS is an interesting CDR technology as it is such a widespread multisectoral and multistakeholder technology that requires you to understand country and regional scale dynamics to characterise its rate of development. Therefore, to clearly outline and explain BECCS’s current state of development, this section has been broken down into regions, USA, Europe, and China. The infrastructure of carbon capture, utilisation and storage CCUS is going to be a main feature of BECCS that is the barrier to it’s installation and therefore the next section will focus on regions.

USA

The USA is a global leader in CCUS and has over 50% of commercial facilities. CO2 from power, natural gas processing, fertiliser, H2 and bio-ethanol plants (USA is a leader in bioethanol plants) are transported in 4500 miles of pipeline, a huge feature of industrial architecture. To put this in perspective, this amount of pipeline is around one fifth of the circumference of the Earth⁷ with 25Mt/y capacity. Four sites in the US from the Carbon Storage Assurance Facility Enterprise (CarbonSAFE) programme, have progressed to phase III for detailed appraisal for storage. Most of the BECCS’s products are used for enhanced oil recovery.

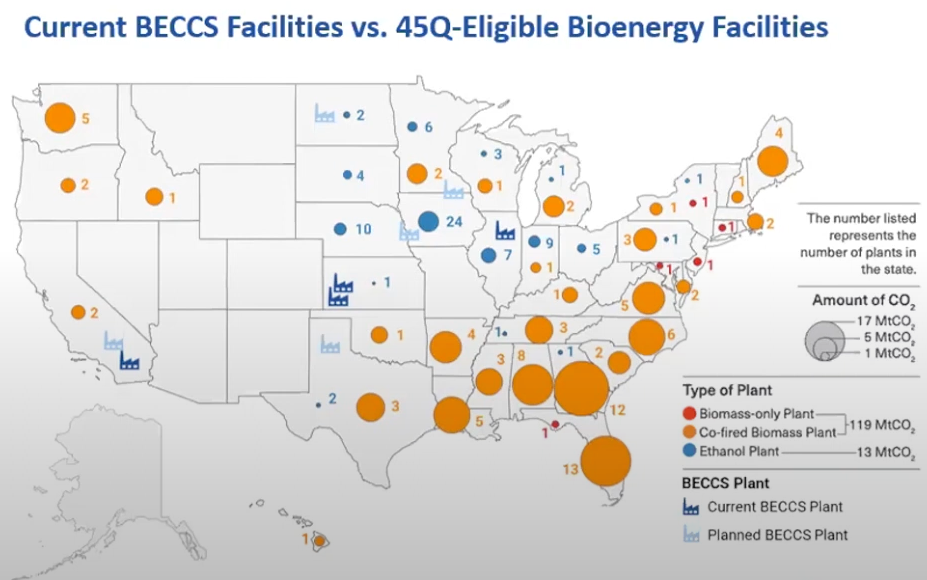

The United States presents several favourable conditions for the implementation of BECCS, which are evidenced in Figure 5. The map illustrates current and planned BECCS projects, in addition to the existing bio-energy facilities, particularly those eligible for the 45Q tax credit for sequestration.

The 45Q tax credit is a financial incentive for companies that capture and store CO2 to reduce their tax liability. Specifically, the tax credit offers a monetary reward of $20 to $50 per metric ton of CO2 captured and stored permanently in geological formations. The credit is intended to encourage companies to invest in technologies such as carbon capture, utilization, and storage, which can reduce greenhouse gas emissions. The tax credit has helped to spur investment in carbon capture and sequestration technologies like BECCS in the United States.

Furthermore, the US boasts high feedstock potential for additional bio-energy production and significant geological storage resources for CO2. These factors combined make the US a suitable location for the development and scaling of BECCS technologies.

Bioethanol is the leading BECCS application with around 40 bioethanol facilities (including around 30 as part of the Midwest Carbon Express Project in the US)⁸ and are planned to start capturing CO2 before 2030, totalling over 15m tCO2e of biogenic carbon capture capacity. Project announcements in the past two years suggest that the BECCS project pipeline is diversifying, with proportionally more capture projects being announced in heat and power, hydrogen, and cement.

Figure 6 above illustrates an expansive technological scope of BECCS. The existing literature on BECCS heavily focuses on the utilization of harvested woods, forestry wastes, post combustion capture, geological storage, and enhanced oil recovery.⁹ However, there remains a vast range of potential feedstocks and durable products and fuels that are yet to be explored within the realm of BECCS. For instance, the production of hydrogen and new capture pathways like the biochar process, when accompanied by an energy co-product, hold great promise for BECCS. It is important to note that the technological readiness of these various pathways varies considerably, with some, such as ethanol and wood combustion, already viable for deployment, while others require more research and demonstration before becoming commercially viable. These findings have been corroborated by the Energy Futures Initiative report on BECCS.

Europe

Europe and the UK are currently leading in the development of BECCS globally, with a commitment for carbon neutrality by 2050. Europe and the UK are definitely progressing through the cluster and hub route when it comes to developing CCUS with sites of high industrial activity and big point source emitters forming clusters that will benefit from a strategically placed network of CO2 capture and transportation hubs for storage.

Scandinavia is developing quickly for BECCS projects, with the Northern Lights projects off the coast of Norway, they are developing an open and flexible infrastructure to transport CO2 delivering carbon storage as a service. The projects are expected to have an annual capacity of 1.5m TCO2 by 2024, 2600 metres under the seabed in permanent underground storage for industries across Europe. There are three other CCS projects around the UK with further development timelines, Net Zero Teesside with capacity of 20m TCO2/year , Humber Net Zero 20m TCO2/year and HyNet NW 8m TCO2/year.

China

China is currently the world’s largest emitter of CO2, and reducing its greenhouse gas emissions is crucial for global efforts to address climate change. While China has set targets to peak its CO2 emissions before 2030 and reach carbon neutrality by 2060, achieving these goals will require significant changes to its energy mix and the deployment of low-carbon technologies such as Bioenergy with Carbon Capture and Storage (BECCS).

One of the challenges for BECCS deployment in China is the large-scale reliance on coal for energy production. Although China has made significant investments in renewable energy such as wind and solar, coal still accounts for around 60% of the country’s primary energy consumption. BECCS can play a crucial role in decarbonizing the power sector by replacing some of the coal-based generation with biomass-based power, coupled with carbon capture and storage to achieve negative emissions.

However, there are some challenges to deploying BECCS in China. One challenge is the availability and sustainability of biomass resources. China has a large population and limited arable land, leading to possible competition for resources like crop residues and wood waste. Additionally, there may be concerns about the sustainability of harvesting and transporting these materials.

To facilitate the deployment of BECCS in China, the government is planning to develop a large number of demonstration projects and hubs. These projects will help showcase the benefits of the technology and build public support for its deployment. Additionally, the government is providing tax incentives for biomass co-firing with agricultural residues, which will encourage the use of these materials for energy production.

BECCS is a necessary technology for achieving deeper decarbonization in the power sector and addressing climate change. Its deployment in China, as the world’s largest emitter of CO2, could play a significant role in global efforts to reduce greenhouse gas emissions. However, it will require careful consideration of the sustainability of biomass resources and the development of supportive policies to encourage its deployment.

AlliedOffsets Database

Currently on the AlliedOffsets Database there are 14 BECCS projects that are selling carbon credits. Nine projects are located in the USA, two in Sweden, and 1 each in Finland, Germany and the UK. The average price of a credit is $300 and the main buyer of all BECCS projects is Stripe.

Challenges and opportunities

BECCS is probably one of the most complicated CDR technologies to develop because of its multi-country and multi-stakeholder nature, spreading over a range of different industries such as agriculture, forestry, transport (land and marine), chemicals, fuels, and geological storage. The steps in the BECCS value chain (e.g., biomass supply, feedstock, preprocessing, bioenergy plant, CO2 storage) are rarely co-located, which means additional and distinct infrastructure to connect them is required.

To maximize the potential benefits of BECCS while minimizing its economic, environmental, and social costs, it is crucial to assess and pinpoint strategic opportunities that align with sustainable biomass supply, existing bioenergy facilities, industrial clusters, and potential CO2 storage sites. This involves a detailed analysis and alignment of these components, taking into account their geographic and logistical considerations.

References:

This blog is mainly based on 2 webinars:

- International Centre for Sustainable Carbon | Global Status of Bioenergy with Carbon Capture, BECCS

- Institute for Carbon Removal Law and Policy: Introduction to Bioenergy with Carbon Capture and Storage